The technological procedure of making inject mold and mildew for plastic bottle

The molding procedure of plastic bottle refers to the procedure of making the last plastic product from the polymer made by the synthetic resin manufacturer. Handling approaches (typically described as single plastic handling) include compression molding (compression molding), extrusion molding (extrusion molding), injection molding (injection molding), impact molding (hollow molding), calendering, and so on.

1 Compression molding compression molding is likewise called compression molding or compression molding. Compression molding is mainly used for molding thermosetting plastics such as phenolic material, urea-formaldehyde material, and also unsaturated polyester material.

2 Extrusion extrusion, likewise called extrusion molding, is an approach that makes use of an extruder (extruder) to continually pass heated material via a mold and mildew to extrude a product of the desired form. Extrusion is sometimes likewise used in the molding of thermoset plastics and can be utilized in the molding of foam plastics. The advantage of extrusion is that items of numerous forms can be squeezed out, the production effectiveness is high, and also it can be automated as well as constant manufacturing; the negative aspect is that thermosetting plastics can not be refined by this approach widely, and also the product size is prone to deviation.

3 shot molding injection molding is also called shot molding. Injection molding is a method of using an injection molding maker (or injection device) to inject thermoplastic melt into a mold under high pressure, and then trendy and strengthen to get an item. Shot molding can additionally be made use of for the molding of thermosetting plastics as well as foam plastics. The advantages of shot molding are fast production speed, high effectiveness, automatic procedure, and the ability to form get rid of complicated forms, which is especially suitable for automation. The downside is that the cost of devices and molds is high, as well as it is difficult to clean the injection molding equipment.

4 impact molding impact molding is likewise called hollow strike molding or hollow molding. Blow molding is a technique in which the warm material parison closed in the mold and mildew is blown into hollow products by the pressure of pressed air. Blow molding includes 2 methods: blown movie and blown hollow products. Blow molding can be utilized to generate film products, numerous containers, barrels, pots, as well as kids’s toys.

5 Calendering is to process the material and also different additives with the predicted treatment (massaging, filtering, and so on) through the space of two or more calender rolls of the calender to be processed into a film or sheet, and after that from the calender roll It is a molding method in which it is removed and then cooled down as well as shaped. Listing is a molding technique primarily utilized for polyvinyl chloride material, which can generate films, sheets, plates, man-made natural leather, flooring ceramic tiles as well as other products.

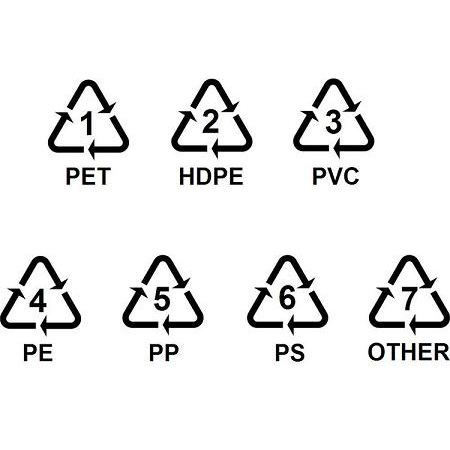

6 foam molding foaming products (PVC, PE, PS, etc.) are included in the suitable frothing agent to make the plastic micro-porous structure. Mostly all thermosetting as well as thermoplastic plastics can be made right into foam. According to the cell framework, it is divided into open-cell foam (most of the pores are connected per other) and closed-cell foam (a lot of the pores are divided from each various other).

This is mainly because of the production technique (divided into chemical lathering, physical lathering) As well as mechanical lathering).