PET (Polyethylene Terephthalate) is a prominent material in the world of cosmetic packaging, renowned for its clarity, strength, and chemical stability.

1. Characteristics:

Transparency: PET offers excellent clarity, making it a preferred choice for showcasing the color and texture of cosmetics.

Stability: The chemical stability of PET ensures it does not react with the ingredients within the cosmetic products, preserving their quality.

Oxidation Resistance: PET acts as an effective barrier against oxygen and contaminants, maintaining the freshness and efficacy of the cosmetics housed within.

2. Applications:

PET is extensively used to create a variety of cosmetic packaging bottles for products such as shampoos, conditioners, facial cleansers, lotions, and essential oils.

It is also a popular choice for the packaging of travel-sized or sample-sized cosmetic products due to its lightweight and durable nature.

3. Manufacturing Process:

Indeed, PET bottles are typically formed through injection molding or blow molding processes. These techniques allow for the efficient production of PET bottles in diverse shapes and sizes.

4. Capacity Range:

In the realm of cosmetic packaging, PET bottles can range in capacity from very small (such as 10ml or less for sample or travel sizes) to larger volumes (like 500ml or more).

The lightweight and durable characteristics of PET make it especially suitable for travel-sized cosmetic packaging.

5. Environmental Considerations:

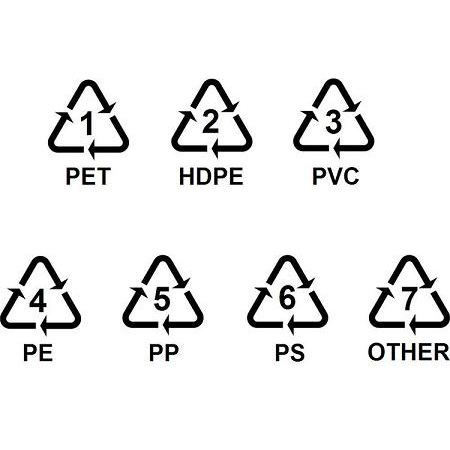

PET is a recyclable material, making PET packaging an eco-friendly option. Many brands are moving towards recyclable and sustainable packaging materials to mitigate environmental impact.

In the cosmetic industry, PET material is favored for its transparency, durability, and chemical stability, establishing it as an ideal choice for packaging liquid and cream-based cosmetics. This information should provide a comprehensive insight into the application of PET material in cosmetic packaging.