Why color disparity exists in different batches of paper printing packaging

In the printing of packaging boxes, we often find that there is a certain color difference between boxes printed in different batches. What are the factors that contribute to these color differences?

Under the same design file, the following factors can cause color differences in different batches of printing:

Paper: Even when using the same brand and model of paper material, there may still be color differences. This is because paper manufacturers produce materials in different batches, and the raw materials they use can vary due to various factors. Insufficient ink absorption by the paper during the printing process can result in color differences.

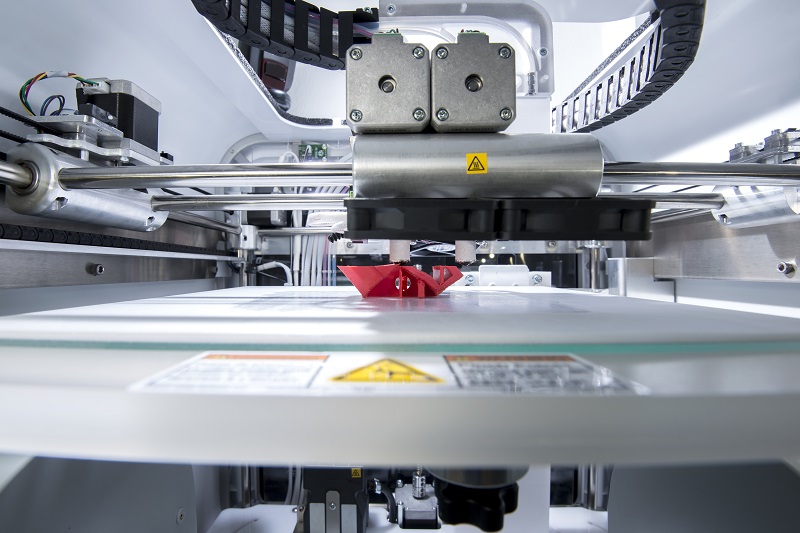

Printing machine: Different printing machines can also lead to color differences in printed packaging boxes. Factors such as machine performance, brand, and model can vary and have an impact during the printing process.

Ink: Even when using the same brand of ink, there can still be printing color differences. This is because various factors such as different ink production batches, environmental conditions, printing machines, and temperature can affect the printing process and result in color variations.

Printer operator: Under the same printing machine, ink, environment, and temperature conditions, different printer operators can also cause varying printing color differences.

Climate and environment: Weather conditions can also contribute to color differences in printed products. Temperature variations between winter and summer, for example, can affect the color output.

In summary, the factors causing color differences in packaging boxes are not singular but influenced by multiple factors mentioned above. It is normal for there to be certain color differences between different batches of printed packaging boxes. Our printing factory in Chengdu performs sample comparisons before each batch of printing to ensure that the color difference in packaging boxes is within 9 percent.