Classification of aluminum foil

Aluminum foil has the advantages of non-toxic, odorless, moisture-proof, good airtightness, and long shelf life. It is widely used in packaging, electromechanical and construction fields, and has become an indispensable and important product in daily life. Let’s take a look at the classification of aluminum foil.

- Thickness

Aluminum foil can be divided into thick foil, single zero foil and double zero foil.

①Thick gauge foil: foil with a thickness of 0.1-0.2mm.

②Single zero foil (medium gauge foil): foil with a thickness of 0.01mm and less than 0.1mm.

③Double zero foil (light gauge foil): Double zero foil refers to an aluminum foil with a thickness of mm after the decimal point with two zero foils, usually less than 0.0075mm thick.

- Shape

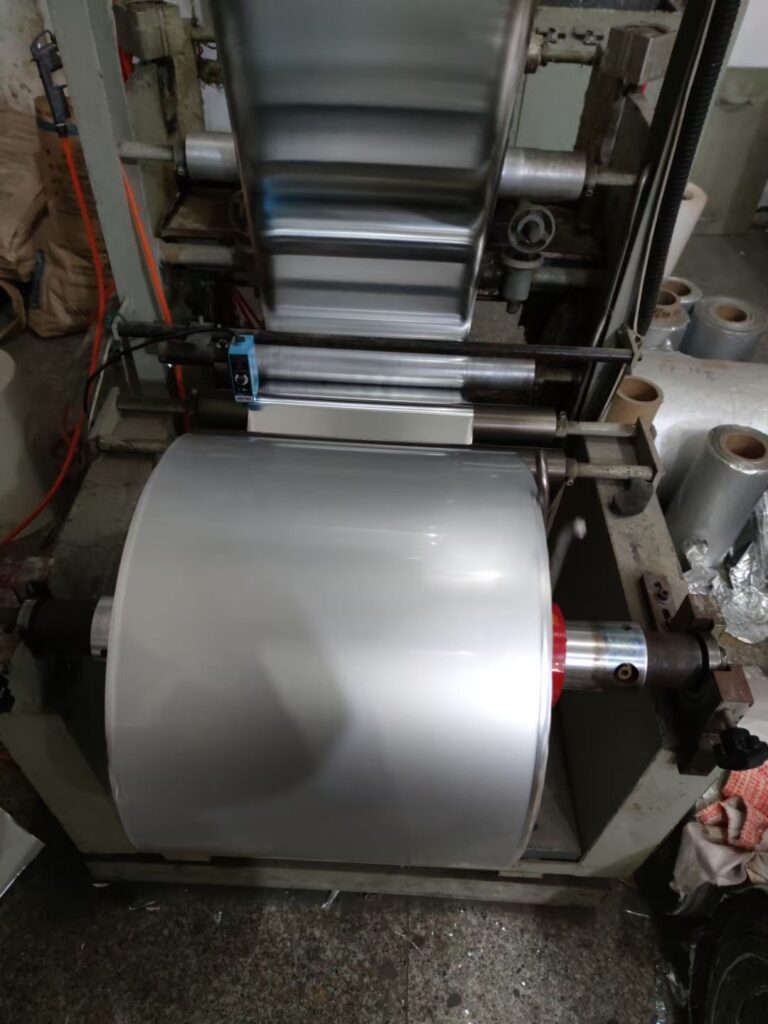

Aluminum foil can be divided into roll aluminum foil and sheet aluminum foil according to shape.

Most of the aluminum foil is supplied in rolls, and only a few handicraft packaging occasions use sheet aluminum foil. According to the state, aluminum foil can be divided into hard foil, semi-hard foil and soft foil.

①Hard foil: The aluminum foil that has not been softened after rolling has residues on the surface when it is not degreased. Therefore, hard foils must be degreased prior to printing, lamination and coating. But it can be used directly for forming.

②Semi-hard foil: The hardness (or strength) of the aluminum foil between the hard foil and the soft foil is usually used for forming.

③Soft foil: The aluminum foil that is completely annealed and softened after rolling is soft, and there is no residual oil on the surface. Soft foils are used in most applications such as packaging, composites, electrical materials, etc.

- Surface condition

Aluminum foil can be divided into single-sided shiny aluminum foil and double-sided shiny aluminum foil.

①Single-sided shiny aluminum foil: double-rolled aluminum foil, one side is bright and the other side is black after sub-rolling. The thickness of single-sided shiny aluminum foil is usually not more than 0.025mm.

②Double-sided shiny aluminum foil: single rolled aluminum foil, both sides are in contact with the roller, and the two sides of the aluminum foil are divided into mirror double-sided shiny aluminum foil and ordinary double-sided shiny aluminum foil due to the different surface roughness of the roll. The thickness of double-sided shiny aluminum foil is generally not less than 0.01mm.

- Processing status

Aluminum foil can be divided into plain foil, embossed foil, composite foil, coated foil, colored aluminum foil and printed aluminum foil.

①Plain foil: aluminum foil that is not processed after rolling, also known as light foil.

②Embossed foil: aluminum foil with various patterns pressed on the surface.

③Composite foil: The aluminum foil is bonded to paper, plastic film and cardboard to form a composite aluminum foil.

④Coated foil: aluminum foil coated with various resins or paints.

⑤Colored aluminum foil: The surface is coated with color.

⑥Printing aluminum foil: The aluminum foil that forms various patterns, patterns, words or pictures on the surface. It can be up to 12 colors.

Leave a comment